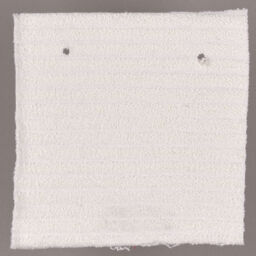

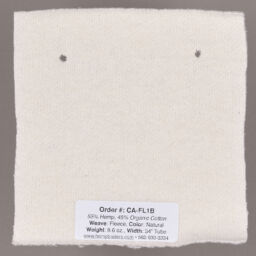

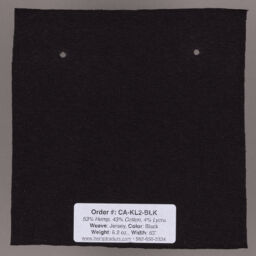

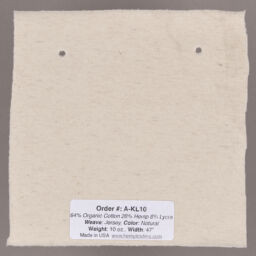

Hemp Traders Hemp Fabric Swatch Book - Knits

Permalink

https://digital.library.illinois.edu/items/41529880-ebd9-013c-4c7d-02d0d7bfd6e4-8Descriptive Information

| Title | Hemp Traders Hemp Fabric Swatch Book - Knits |

| Alternative Title | Fabric swatch |

| Creator | Hemp Traders |

| Date | 2023-02 |

| Geographic Location | Los Angeles (Ca.) |

| Dimensions | 6 x 6 in. |

| Specifications | Specification sheets for materials available upon request. Please email rickerlibrary@library.illinois.edu. |

| Typical Use |

|

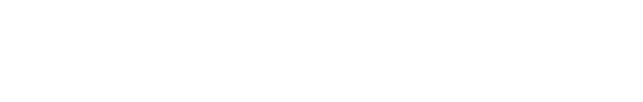

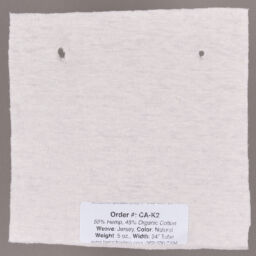

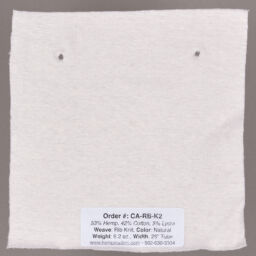

| Description | Bound sample booklet of knit Hemp fabrics. Includes jersey fabrics, rib knits, specialty knits, and stretch hemp |

| Source | Hemp Traders |

| Materials |

|

| Materials Color | Multicolor |

| Materials Techniques | Hemp fabric is typically produced through a process that involves harvesting hemp stalks, separating the fibers from the woody core (decortication), and then processing the fibers for spinning into yarn and weaving into fabric. The process may include retting, breaking, scutching, and carding to refine the fibers. After weaving, the fabric can undergo finishing processes such as dyeing and softening. |

| Format | Antimicrobial, abrasion resistant, UV resistant, dimensionally-stable, water absorbent (hygro-thermal), hypoallergenic |

| Type | Physical object |

| Sensory Properties | Touch: soft |

| Rights | In Copyright - Educational Use Permitted |

| Container | Box 10 |

| Local Identifier | RMC_0142 |

| Barcode | 30112097659681 |

| Collection | Ricker Materials Collection |

| Repository | Ricker Library of Architecture and Art |

| Collection | Ricker Materials Collection |

Download Options

|

RMC_0142-001 | |

|

RMC_0142-002 | |

|

RMC_0142-003 | |

|

RMC_0142-004 | |

|

RMC_0142-005 | |

|

RMC_0142-006 | |

|

RMC_0142-007 | |

|

RMC_0142-008 | |

|

RMC_0142-009 | |

|

RMC_0142-010 | |

|

RMC_0142-011 | |

|

RMC_0142-012 | |

|

RMC_0142-013 | |

|

RMC_0142-014 | |

|

RMC_0142-015 | |

|

RMC_0142-016 | |

|

RMC_0142-017 | |

|

RMC_0142-018 | |

|

RMC_0142-019 | |

|

RMC_0142-020 | |

|

RMC_0142-021 | |

|

RMC_0142-022 | |

|

RMC_0142-023 | |

|

RMC_0142-024 | |

|

RMC_0142-025 | |

|

RMC_0142-026 | |

|

RMC_0142-027 | |

|

RMC_0142-028 | |

|

RMC_0142-029 | |

|

RMC_0142-030 | |

|

RMC_0142-031 | |

|

RMC_0142-032 | |

|

RMC_0142-033 | |

|

RMC_0142-034 | |

|

RMC_0142-035 | |

|

RMC_0142-036 | |

|

RMC_0142-037 | |

|

RMC_0142-038 | |

|

RMC_0142-039 | |

|

RMC_0142-040 | |

|

RMC_0142-041 | |

|

RMC_0142-042 | |

|

RMC_0142-043 | |

|

RMC_0142-044 | |

|

RMC_0142-045 | |

|

RMC_0142-046 | |

|

RMC_0142-047 | |

|

RMC_0142-048 | |

|

RMC_0142-049 | |

|

RMC_0142-050 | |

|

RMC_0142-051 | |

|

RMC_0142-052 | |

|

RMC_0142-053 | |

|

RMC_0142-054 | |

|

RMC_0142-055 | |

|

RMC_0142-056 | |

|

RMC_0142-057 | |

|

RMC_0142-058 | |

|

RMC_0142-059 | |

|

RMC_0142-060 | |

|

RMC_0142-061 | |

|

RMC_0142-062 | |

|

RMC_0142-063 | |

|

RMC_0142-064 | |

|

RMC_0142-065 | |

|

RMC_0142-066 | |

|

RMC_0142-067 | |

|

RMC_0142-068 | |

|

RMC_0142-069 | |

|

RMC_0142-070 | |

|

RMC_0142-071 | |

|

RMC_0142-072 | |

|

RMC_0142-073 | |

|

RMC_0142-074 | |

|

RMC_0142-075 | |

|

RMC_0142-076 | |

|

RMC_0142-077 | |

|

RMC_0142-078 | |

|

RMC_0142-079 | |

|

RMC_0142-080 |

Contact us

for questions and to provide feedback.